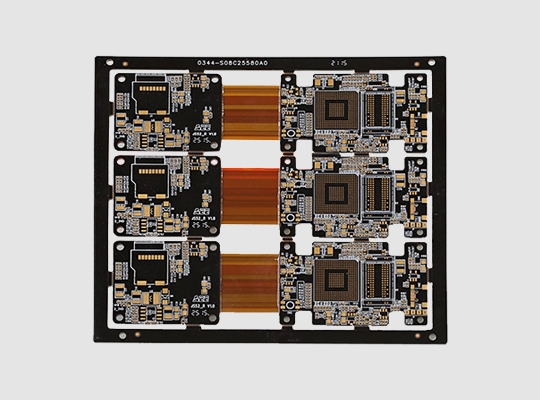

Military Rigid-flex 8Layer ENIG FR4+PI+NFPP

The rigid-flex PCB is a printed circuit board formed by the clever design and connection of a thin layer of flexible bottom layer and a rigid bottom layer, which is then pressed into a single component. It has changed the traditional planar design concept and expanded to the three-dimensional space concept, bringing great convenience to the design of electronic products.

The application range of the rigid-flex PCB mainly includes advanced medical equipment, digital camera, portable camera, high quality MP3 player and aerospace. Its main advantages are as follows:

1. Realize three-dimensional assembly, save assembly space, and make electronic products smaller and lighter;

2. The design of the rigid-flex PCB can use a single component to replace the composite PCB connected by multiple connectors, multiple cables and ribbon cables. And the performance is stronger, the stability is higher.

The application range of the rigid-flex PCB mainly includes advanced medical equipment, digital camera, portable camera, high quality MP3 player and aerospace. Its main advantages are as follows:

1. Realize three-dimensional assembly, save assembly space, and make electronic products smaller and lighter;

2. The design of the rigid-flex PCB can use a single component to replace the composite PCB connected by multiple connectors, multiple cables and ribbon cables. And the performance is stronger, the stability is higher.

| Layer Count | 8 Layers |

| Material | FR4+PI+NFPP |

| Finished Board Thickness | 2.4 mm |

| Finished Copper Thickness | 1 OZ |

| Min. Drilling | 0.2mm |

| Min. Wall Cu Thickness | 25um |

| Min. Line Width/Space | 3/3mil |

| Surface Treatment | Immersion Gold |

| Speciality | IPC Class 3 |

| Application | Military |